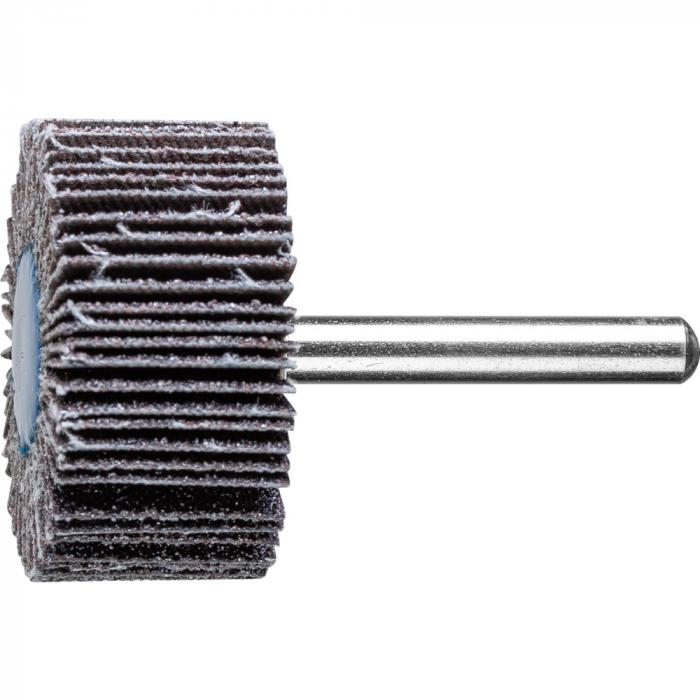

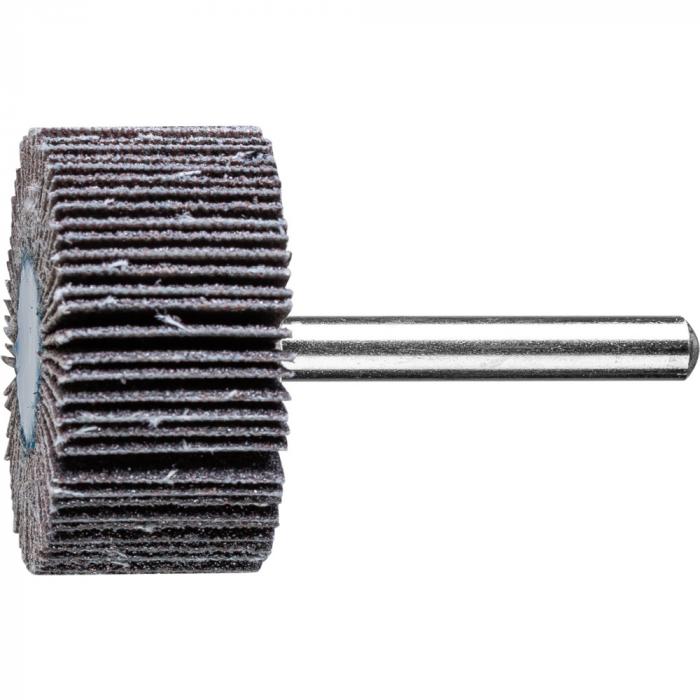

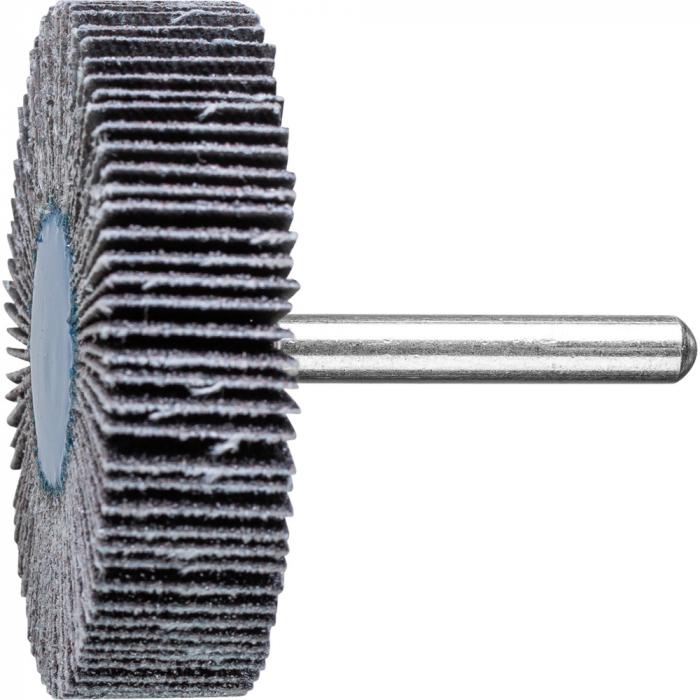

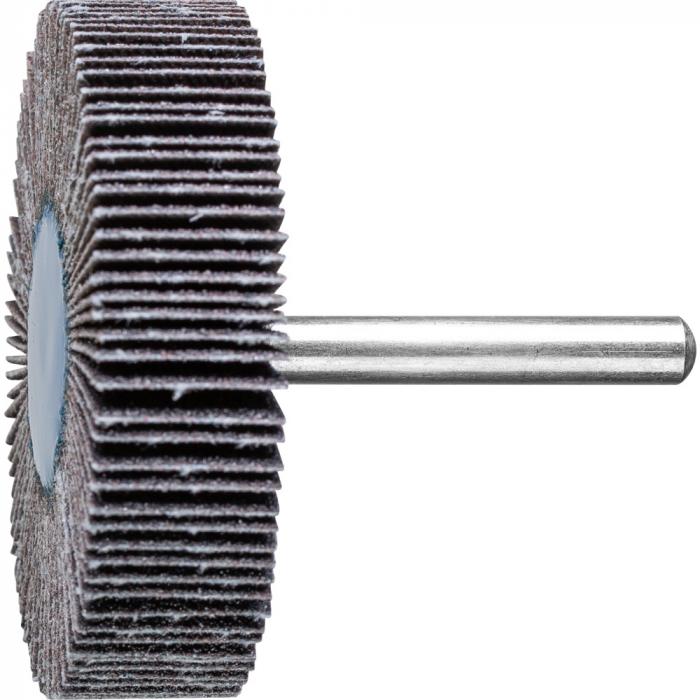

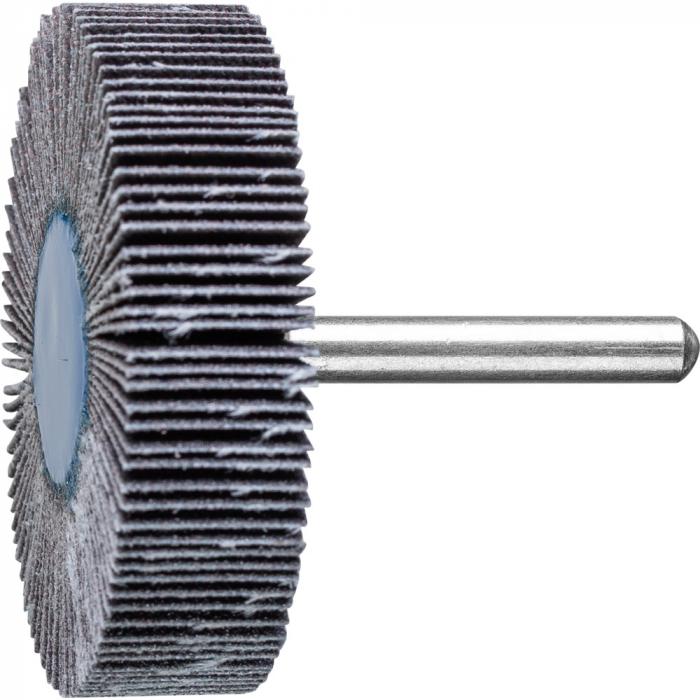

Product Description

- PFERD flap grinders are suitable for universal grinding tasks on components made of aluminum, copper, bronze, titanium, titanium alloys and fiber-reinforced plastics.

- The tool is ideally suited for the aircraft industry, if for the machining of z. B. drive parts only SiC is approved.

- The high flexibility enables ideal adaptation to the contour of the workpiece.

- The flap grinders ensure a consistently high material removal over the entire service life, as new, aggressive abrasives are constantly being released.

- A flat cast core construction enables a frontal use very close to edges and at angles.

- The fan grinders are extremely economical thanks to their high grinding performance and service life.

- The best results are achieved at a cutting speed of 15 to 20 m / s.

- For security reasons, the max. permissible speed are not exceeded.

- The clamping length of the shaft must be at least 15 mm.

- Use grinding oil that is suitable for the material in order to significantly increase the service life and grinding performance of the tools.

- Abrasives - silicon carbide

- Outside-ø x width - 20 x 10 to 60 x 15 mm

- Shank ø - 6 mm

- Shaft length - 40 mm

- Grain size - 60 to 150

- Opt.RPM - 6,300 to 19,000

- Max RPM - 12,700 to 38,100

- Standard - ISO 3919

- VE - 10 pieces