Product Description

- Thanks to its special design, the DAPS rotary actuator is ideal for use in the process industry. It is suitable for use with compressed air. Thanks to the connection diagram in accordance with Namur VDI/VDE 3845, solenoid valves can be easily mounted on the rotary actuator.

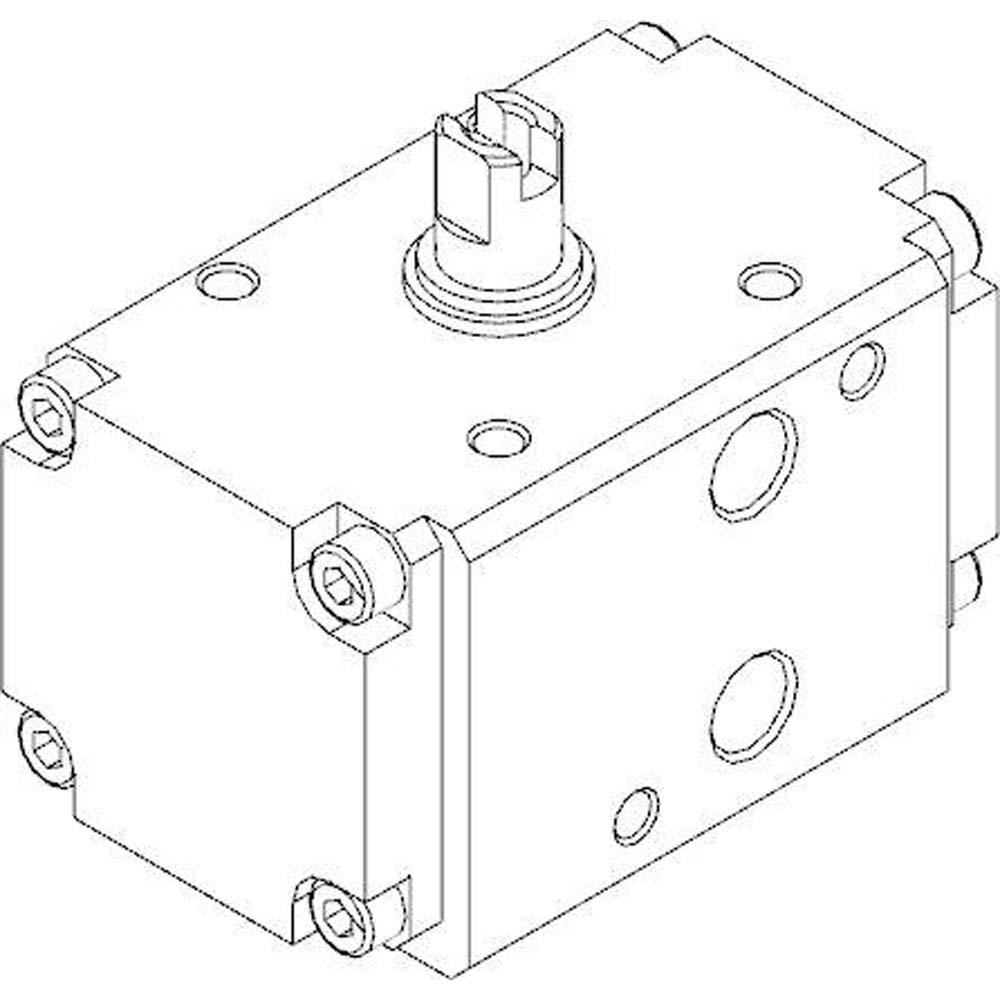

- The cover and housing of the DAPS rotary actuator are made of aluminium, while the shaft and screws are made of high-alloy steel. It also features FKM, NBR and PUR seals. The materials used are RoHS compliant. The lever-swing kinematics generate the torque required to overcome high breakaway torques in the valve, which is a great advantage. Thanks to their robustness and torque gradation, DAPS rotary actuators are mainly used to control valves through which media flows, such as ball valves and butterfly valves. The maximum rotation angle is 90°. The rotary actuator impresses with its compact design, its torque curve adapted to process valves and its low wear, which is made possible by simple and robust mechanics.

- Housing material – wrought aluminium alloy

- Cover material – wrought aluminium alloy

- Shaft material – high-alloy steel 1.4305

- Material of screws – high-alloy steel

- Seal material – FKM, NBR, PUR

- Material information – RoHS compliant

- Installation position – any

- Functionality – double-acting

- Damping – no damping

- Design structure – yoke kinematics

- Position detection – without

- Closing direction – right-hand closing

- Standard connection to valve – ISO 5211

- Valve connection complies with standard VDI/VDE 3845 (NAMUR)

- Safety Integrity Level (SIL) – product can be used in SRP/CS up to SIL 2 Low Demand

- CE mark (see declaration of conformity) – in accordance with EU explosion protection directive (ATEX)

- ATEX category Gas - II 2G

- ATEX category Dust - II 2D

- Ex ignition protection type gas - Ex h IIC T6...T3 Gb X

- Ex ignition protection type Dust - Ex h IIIC T85°C...T200°C Db X

- Ex ambient temperature - -20°C

- Operating medium – compressed air in accordance with ISO 8573-1:2010 [7:4:4]

- Note on operating and control medium - Oiled operation possible (required for further operation)

- Corrosion resistance class KBK - 3 - high corrosion exposure

- Ambient temperature - -20°C to 80°C

- Swivel angle - 90°

- Adjustment range End position at 0° - -1° to 9°

- Operating pressure – 1 to 8.4 bar

- Nominal operating pressure – 5.6 bar

- Torque at nominal operating pressure and 0° swivel angle – 7.0 to 480.0 Nm

- Torque at nominal operating pressure and 50° swivel angle – 3.5 to 240.0 Nm

- Torque at nominal operating pressure and 90° swivel angle – 7.0 to 360.0 Nm

- Note on torque – The operating torque of the actuator must not exceed the maximum permissible torque specified in ISO 5211, based on the size of the mounting flange and the coupling.

- Actuator size - 0008 to 0480

- Flange drilling pattern - F03, F04, F03F05, F05F07, F07F10, F10F12

- Shaft connection depth – 10.1 to 29.5 mm

- Shaft connection - T9 to T27

- Pneumatic connection – G 1/8" to G 1/4"

- Air consumption at 6 bar per cycle 0°-90°-0° - 0.24 to 18.20 l

- Product weight - 300 to 9600 g

Further details and dimensions can be found in the data sheet.