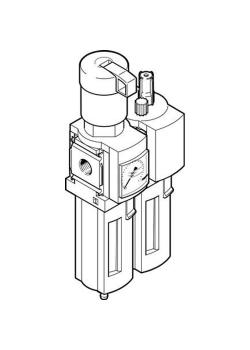

FESTO - MSB4-1/4-FRC13:J120M1 (8042669) Service unit combination - pressure gauge with manometer - size 4 MS series

| € 136,89 |

| Price incl. VAT |

| plus € 29,00 shipping costs |

Delivery time 2 - 4 working days

Do you have any questions?

We would like to assist you!

We would like to assist you!

Item No.:

351001005914

Product Description

- The maintenance device is suitable for maintenance in compressed air technology.

- The size 4 service unit from the MS series has a manually rotating condensate drain and a plastic protective cage.

- The maintenance unit also has a pressure indicator with pressure gauge.

- Size - 4

- Series - MS

- Actuation lock - rotary knob with lock can be locked with accessories

- Installation position: vertical ± 5°

- Filter fineness - 40

- Condensate drain - manually rotating

- Design structure: Filter regulator with pressure gaugeProportional standard mist lubricator

- Regulator function - outlet pressure constantwith reverse flow behaviourwith secondary flow

- Tray guard - plastic protective cage

- Pressure indicator - with pressure gauge

- Operating pressure - 1.5 to 14 bar

- Pressure regulation range - 0.5 to 7 bar

- Standard nominal flow rate - 1,400 l/min

- Operating medium - Compressed air according to ISO 8573-1:2010 [7:4:4]Inert gases

- Note on the operating and control medium - Lubricated operation possible (required for further operation)

- Corrosion resistance class KBK - 2 - moderate corrosion stress

- Storage temperature - -10 to 60

- Food suitability - see extended material information

- Air purity class at outlet - compressed air according to ISO 8573-1:2010 [7:4:-]

- Medium temperature - -10 to 60 °C

- Ambient temperature - -10 to 60

- Product weight - 500 g

- Mounting type: with accessories

- Pneumatic connection 1 - G1/4

- Pneumatic connection 2 - G1/4

- Housing material - die-cast aluminium

- Shell material - PC

Ratings

No evaluation has been given