Product Description

- The single-acting DAPS-1920 rotary actuator from Festo is suitable for applications where a secure return position is required thanks to an integrated spring – for example in process engineering, energy supply, water and wastewater technology, and in potentially explosive areas.

- ATEX approval, high corrosion resistance (KBK 3) and an extended temperature range down to -50 °C make it particularly reliable and durable – even under extreme environmental conditions.

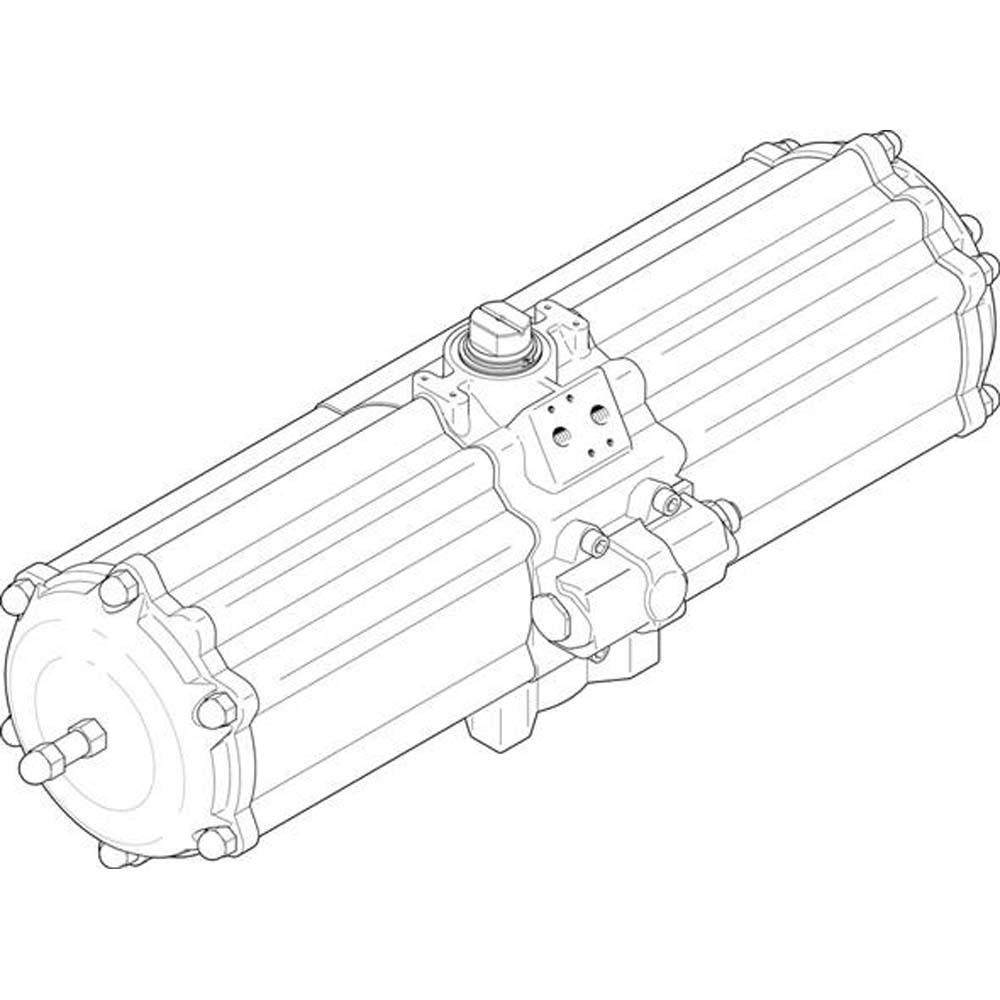

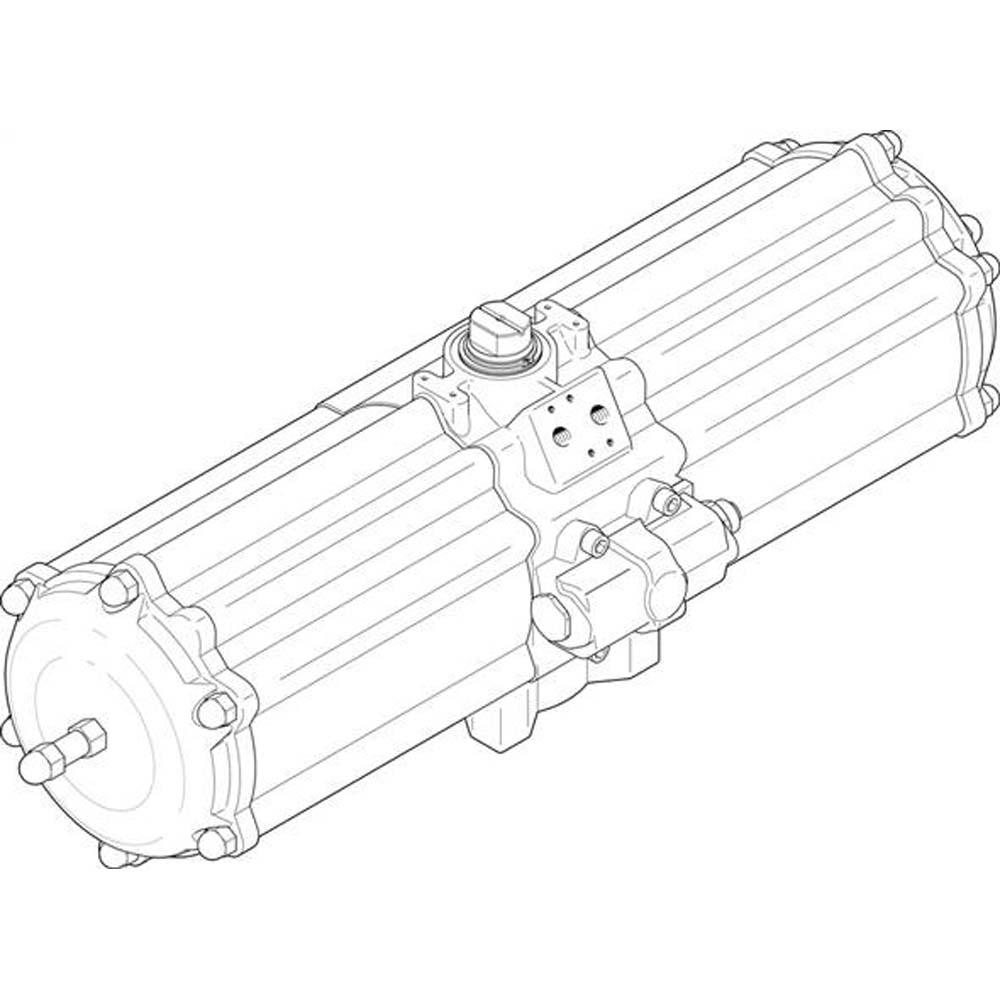

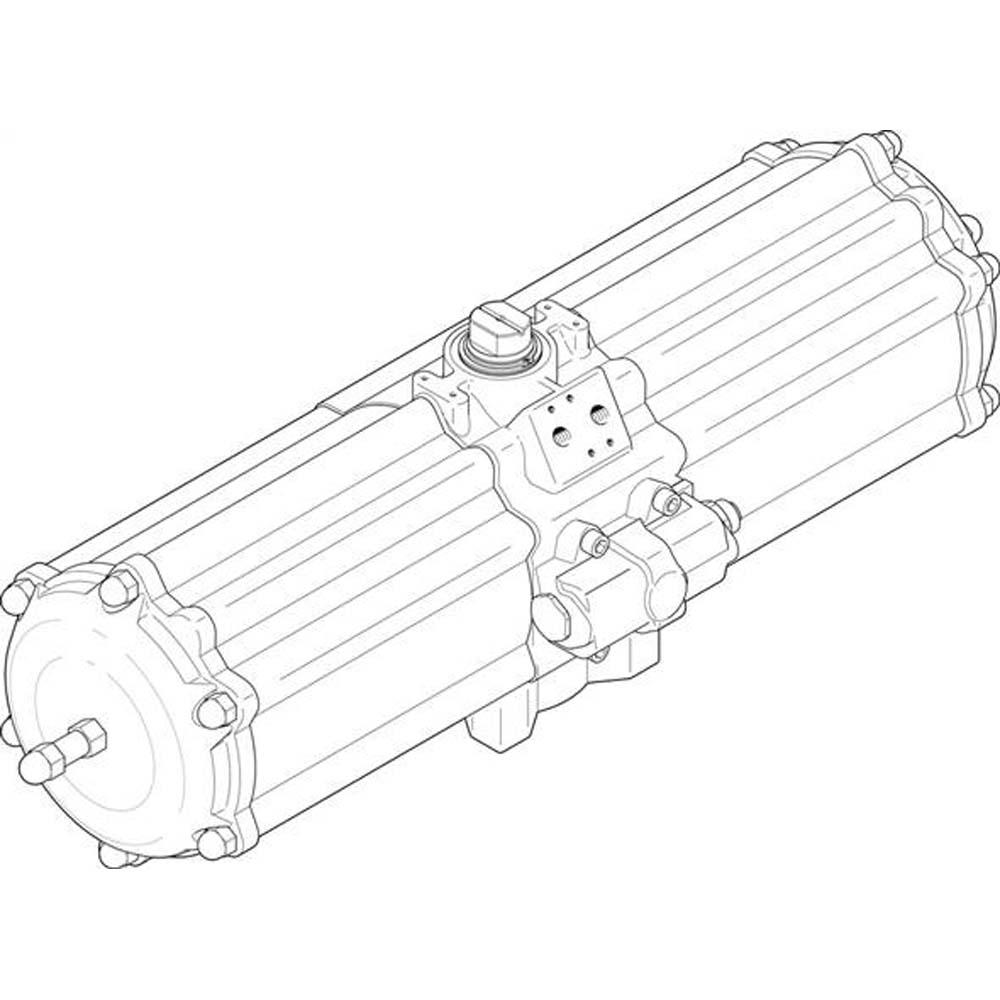

- The Festo DAPS-1920 rotary actuator is a powerful, single-acting pneumatic actuator with yoke kinematics.

- Thanks to an integrated return spring, the actuator reliably returns to its initial position in the event of a pressure drop.

- With its robust design, standard connections in accordance with ISO 5211 and VDI/VDE 3845 (NAMUR), and suitability for ATEX zones (II 2G/2D), the DAPS-1920 is ideal for safety-critical applications in industrial environments.

- Three variants with different spring strengths enable precise adjustment to the respective requirements in terms of torque and control pressure.

- Actuator size - 1920

- Functionality – single-acting with return spring

- Design structure – yoke kinematics

- Swivel angle - 90°

- Adjustment range End position at 0° - -5° to +5°

- Adjustment range End position at 90° - 85° to 95°

- Shaft connection / depth - T46 / 49.0 mm

- Pneumatic connection - G3/8

- Flange drilling pattern - F16

- Standard connection to valve – ISO 5211

- Valve connection complies with standard VDI/VDE 3845 (NAMUR)

- Damping – no damping

- Installation position – any

- Position detection – without

- Closing direction – right-hand closing

- SIL (Safety Integrity Level) – up to SIL 2 (low demand), suitable for SRP/CS

- CE marking – in accordance with EU explosion protection directive (ATEX)

- ATEX category Gas / Dust - II 2G / II 2D

- Ex ignition protection type gas - Ex h IIC T6...T3 Gb X

- Ex ignition protection type Dust - Ex h IIIC T85°C...T200°C Db X

- Ex ambient temperature - -50 °C to +60 °C

- Ambient temperature - -50 °C to +60 °C

- Operating medium Compressed air – according to ISO 8573-1:2010 [7:4:4]

- Note on operating medium - Gel operation possible (permanently required)

- Corrosion resistance class (KBK) - 3 - severe corrosion exposure

- Materials - wrought aluminium alloy, FVMQ/PTFE (seals), high-alloy steel

- Material number shaft - 1.4305

- Material information – contains LABS-containing substances, RoHS compliant

- Air consumption at 6 bar (cycle 0°–90°–0°) – 91.70 l

- Weight - 67 kg

- Price per item

The choice of the appropriate spring force depends on the available control pressure and the required reset torque.