Product Description

- The microfilter from Festo is ideal for compressed air treatment in industrial plants, for protecting pneumatic components and measuring systems, for applications with high air purity requirements, laboratory, production and automation systems, and for use with inert gases (nitrogen, argon, etc.).

- The Festo LFMA-D microfilter with manual condensate drain and differential pressure indicator is designed to meet the highest requirements in compressed air treatment.

- It removes the finest oil and dirt particles down to 0.01 µm with a filter efficiency of 99.9999%.

- The user can drain the condensate manually by turning a valve, and the visual differential pressure indicator reliably signals the level of contamination.

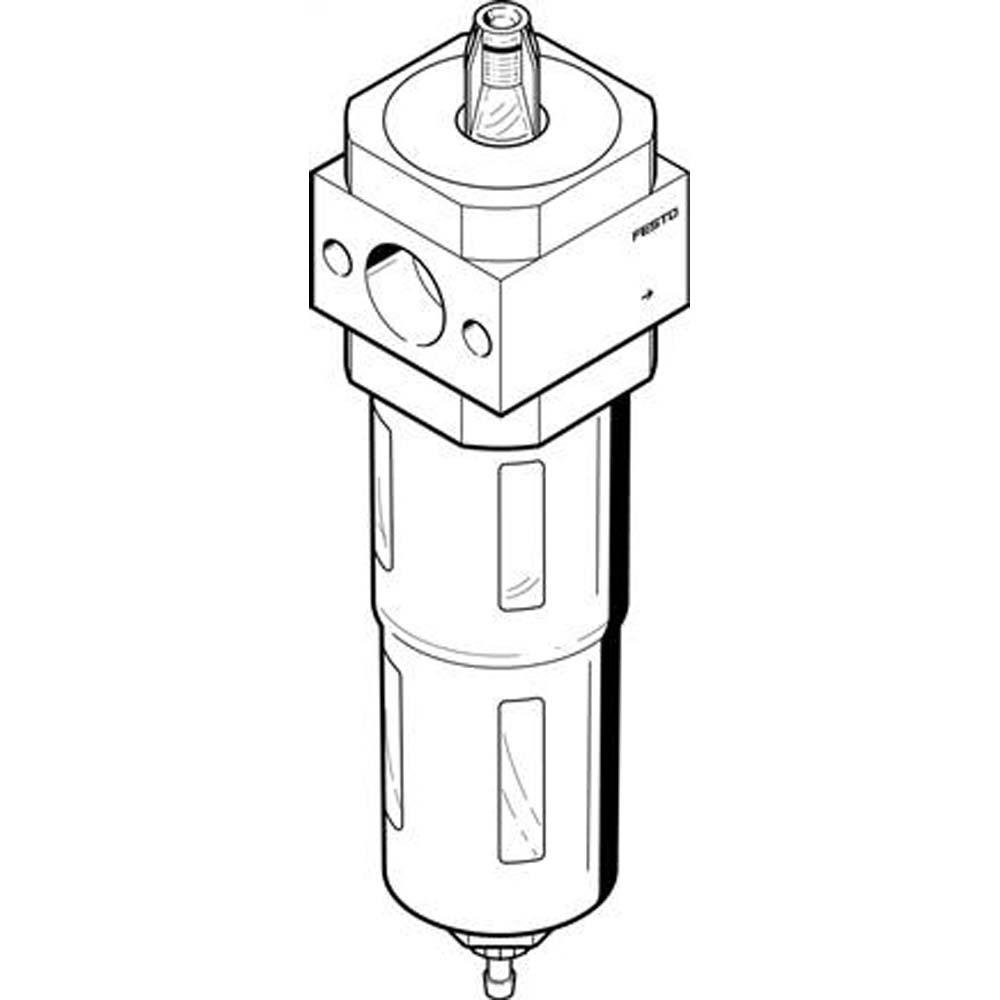

- The robust die-cast zinc housing, metal protective basket and PC shell provide mechanical protection.

- The filter is copper- and PTFE-free, RoHS-compliant and suitable for moderate corrosion exposure (CRC / KBK class 2).

- Thanks to a nominal operating pressure range of 1 to 16 bar and compatibility with compressed air in accordance with ISO 8573-1:2010 [6:8:4] (inert gases), the filter delivers purity at the outlet in accordance with ISO 8573-1:2010 [1:7:2].

- Suitable for demanding pneumatic systems, precision equipment and transport routes with sensitive components.

- Series - D

- Size - Mini / Midi / Maxi

- Design - Fibre filter

- Filter fineness – 0.01 µm

- Filter efficiency [%] - 99.9999

- Operating pressure – 1 to 16 bar

- Operating medium – compressed air according to ISO 8573-1:2010 [6:8:4] / inert gases

- Air purity class at outlet – ISO 8573-1:2010 [1:7:2]

- Condensate drain – manual rotary

- Differential pressure indicator – visual indicator

- Corrosion resistance class (CRC) - 2 – moderate stress

- Media temperature - 1.5 to 60 °C

- Ambient temperature - - 10 to 60 °C

- Residual oil content – 0.01 mg/m³

- Installation position – vertical ± 5°

- Mounting type - Pipe installation (with accessories)

- Pneumatic connection – connection plate (port 1 / port 2)

- Housing material – die-cast zinc

- Filter material – borosilicate fibre

- Shell material – polycarbonate

- Shell protection – metal protective cage

- Material information – Copper and PTFE-free, RoHS-compliant